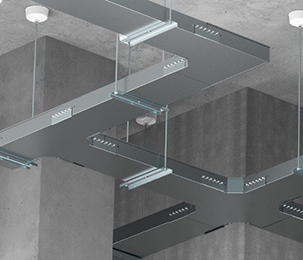

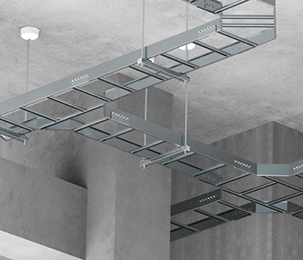

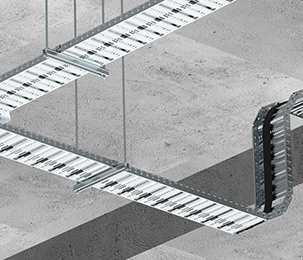

Energy-saving weather-resistant cable tray series

Using the molding reinforcement process, there are convex ribs stamped on the side of the bridge and the bottom plate to strengthen the structure, and increase the heat dissipation area; There is a large-area hollow process at the bottom, which can be used for ventilation and heat dissipation and offline function. The surface is smooth, the ventilation and heat dissipation performance is excellent, and the line loss is effectively reduced. Combined with the characteristics of mesh bridge and ladder frame, it can be taken off the line at any position, which is convenient and flexible, and can make elbows and line diversions on site, which solves the problem that the project cannot be carried out once the traditional bridge modular accessories are missing; At the same time, the use of fewer and smaller parts greatly reduces the cost of parts, thereby reducing the overall cost of the project. Under the condition of high load-bearing requirements, the opening rate exceeds 30%, which is integrated with other cable trays, making it a perfect solution for data center power cables.