1. Forebody of grid cable tray

In the modern data center, communication and computer room, the previously closed cable tray has been gradually replaced. Now, in the construction of the computer room, the pursuit is light, simple installation and easy maintenance in the later period. Based on the evolution of the above point, this kind of fully exposed and semi open cable tray is the predecessor of grid cable tray.

2. What is the grid cable tray?

Grid cable tray: literally, it is a cable tray with grid structure, which is a modern derivative of traditional cable tray. It inherits the advantages of traditional cable tray, such as high stability, light deadweight, good effect of fixed cables, and magnifies. It is a semi open full bare cable tray, which is superior to traditional cable tray in terms of cable maintenance and calculation of cable tray service life in the later period. Its essence is that the steel wire is welded and shaped into wire mesh, then cooled and bent, and then customized according to the site construction requirements for width, and then galvanized, plastic sprayed, hot galvanized and other surface treatment methods.

What are the installation methods of grid cable tray suspension series?

3. What are the accessories of grid cable tray?

Galvanized cross arm ofnew SUNPLN grid cable tray: it is surface treated after steel sheet stamping, and can be used for fixing grid cable tray in different construction environments such as installation of grid cable tray cabinet top, ceiling installation and ground installation. It can be called universal fitting of grid bridge.

What are the advantages of wire mesh cable tray?

new SUNPLN grid cable tray galvanized reinforcing strip: it is made of steel plate after punching and surface treatment. It can be used for grid cable tray wiring installation process such as turning in the wiring of the machine room, three-way and four-way.

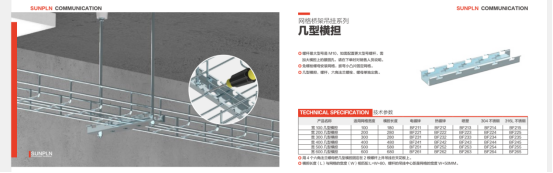

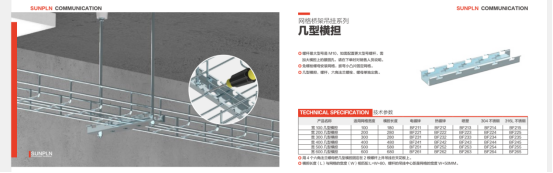

1.C CHANNEL BAR

C CHANNEL BAR

When selecting and purchasing the C-shaped steel cross arm, it must be noted that it is different from other installation accessories, and its cross arm length is the width of the grid+100mm. Many people have to ask, what about the center distance of the suspension? The grid width is+50mm. If our grid width is 100mm, then the center distance is 150mm. Of course, you can also adjust the center distance according to your actual situation. For the installation of C-shaped steel cross arm, the flange nut is used to connect the screw with the cross arm, and the expansion connection between the screw and the ceiling. The grid is directly connected with the cross arm and only needs to be fixed by pressing.

2.Ω BRACKET(ROOF)

Ω BRACKET(ROOF)

This model is installed without bolts. It is different from the C-shaped steel cross arm above. The upper part needs to be fixed by pressing plates. For this model, it can be fixed by directly pressing the convex plates. Of course, it should be noted that the length of this cross arm is the grid width+80mm. The center distance is constant, that is, it is based on the grid width+50mm. During installation, it is only necessary to use flange nuts to connect with several types of cross arms, and suspenders to connect with the ceiling.

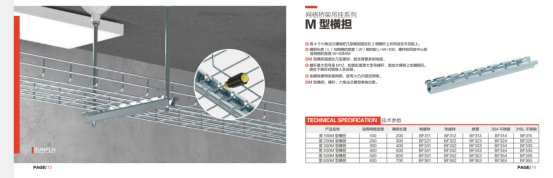

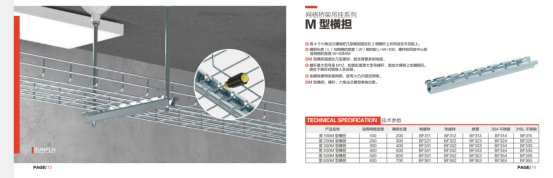

3.M BRACKET(SUPPORT)

M BRACKET(SUPPORT)

12# ANGLE SUPPORT

The M-type cross arm is recommended for use, because its supporting force is better than that of several types of cross arms, and it can support more cables. It is suitable for the environment where many cables are required for on-site installation. Note that the length of this cross arm is grid width+100mm. Whether the center distance is constant or the grid width is+50mm. During installation, nuts are also used to connect with cross arms, and suspenders are used to connect with the ceiling.

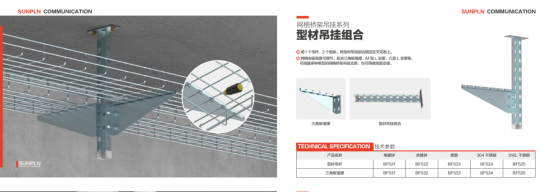

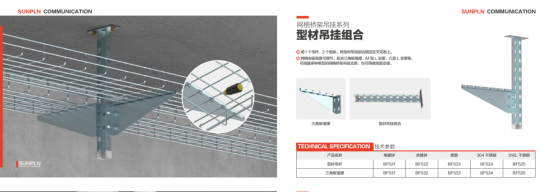

4. Profile hanging combination

If the profile is hung, the installation is flexible, because in addition to the hanging, the triangle plate support can be replaced, which can be replaced by several types of supports, L-shaped supports, etc. It is more practical in combination. First, the expansion handle hanger is used to connect with the ceiling, and then the triangle plate is connected with the hanger with bolts and nuts. The height can also be adjusted during installation, which is convenient. It is also suitable for different environments and can also be used as ground support.

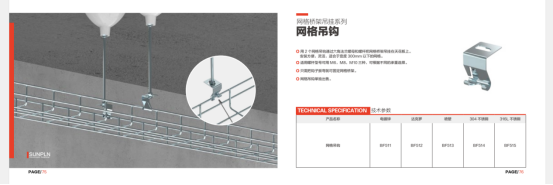

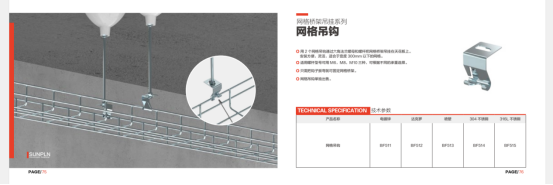

5. Mesh hook

M14 THREADED RODE

There are restrictions on the use of grid hooks, because they are applicable to grid bridges with a width of less than 300. However, the installation is very convenient. Just bend the hook to fix the grid, isn't it convenient??

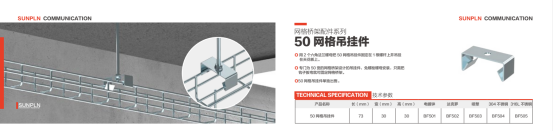

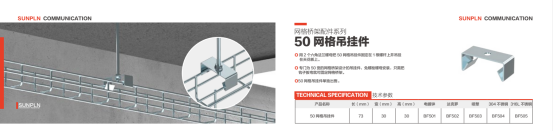

6. 50 grid hanger

BRACKET(SUPPORT)

50 grid hanger, as the name implies, is specially prepared for the 50mm wide grid. Only one screw is needed, and no bolts and nuts are needed. Just bend the hanger to fix the grid. It is the same as the grid hook above, but it is dedicated to the 50mm grid. It's very convenient!

After talking about so many ways of hanging and installing, I wonder which one of the new SUNPLN technologies is most popular? Of course, it is also nec

essary to select the one that is suitable for you according to the actual situation of the site construction, with reference to environmental factors, cost budget, installation convenience, etc.

Home

Home