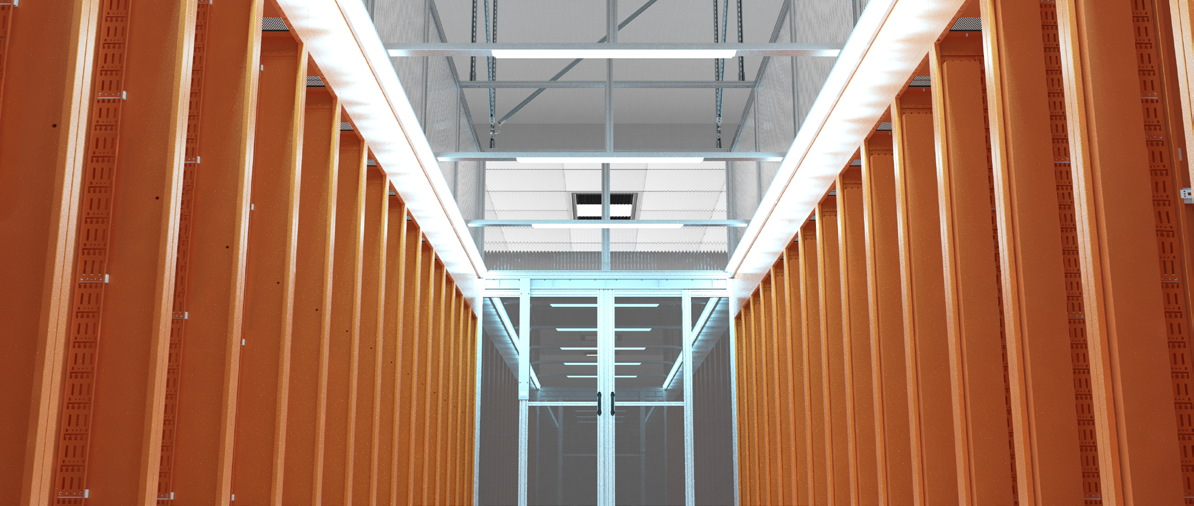

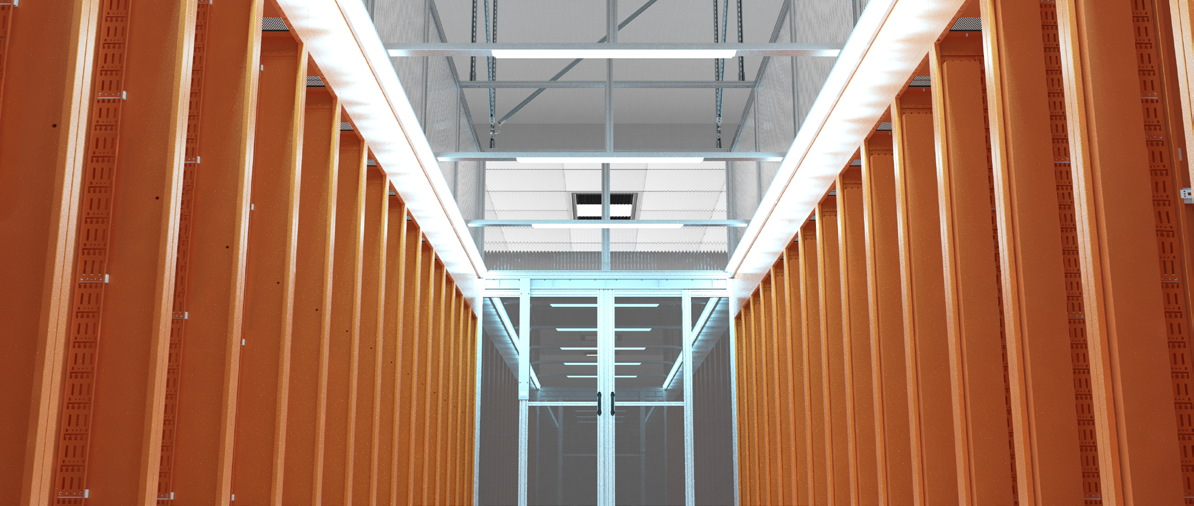

The hot aisle enclosure is composed of lightweight aluminum profiles and heat-insulating polycarbonate plates, which plays a direct role in enhancing heat dissipation and saving energy in high-density demand computer rooms. Superior heat dissipation compared to cold aisles and a more modular assembly structure, it is widely used in various large-capacity data centers.

In the layout of data centers, cabinets are usually arranged back-to-back, thus forming hot aisles behind the cabinets. Then, by installing some sealing materials, such as glass doors and top plates, the hot passage is enclosed, just like adding a "wall" to the hot passage.

When the server is working and generates hot air, this hot air will be discharged from the rear of the cabinet and enter a closed hot channel. Since the hot air passage is closed, the hot air can only flow along this passage and is eventually sent to the return air outlet of the air conditioner for cooling treatment. In this way, the hot air is prevented from spreading around the computer room and mixing with the cold air, thereby improving the efficiency of the refrigeration system.

For instance, the hot aisle closure system is like an efficient "garbage classification" system, separating and processing the two types of "garbage", hot air and cold air, allowing them to play their respective roles, thereby enhancing the "environmental protection" level of the entire data center, that is, energy efficiency. In this way, the hot aisle closed system can effectively increase the return air temperature of the air conditioner, lower the ambient temperature of the computer room, thereby significantly improving the cooling efficiency and contributing to energy conservation and consumption reduction in the data center.

Home

Home